Production and Quality perfectly organized

We can do more.

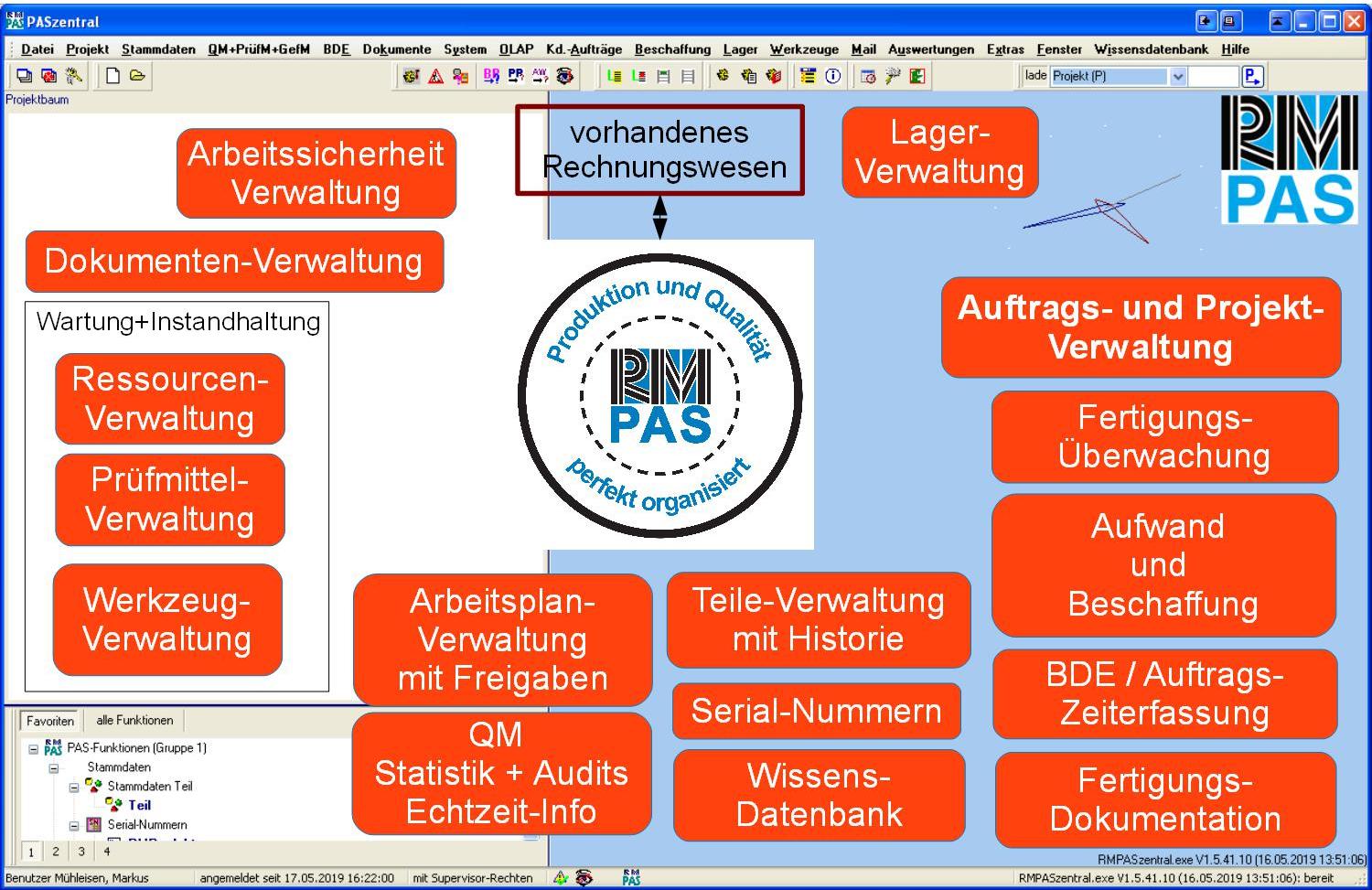

Our software system RM-PAS provides the possibility to coordinate and structure all our processes with a clear focus on quality, process safety in combination with traceability and a intuitive, quick access to all information.

This enables our customers to have changes realized, even concerning parts already in the production chain, to adapt to modifications, to monitor the process by applying additional measures to ensure the quality, to add serial numbers or quantities subsequently and to integrate those immediately in the production plan, to produce the components and finally deliver them to you.

RM-PAS software has been developed especially for us as pilot customer and is permanently extended and maintained. By means of the extensive functions in the RM-PAS we can e. g. keep our warehouse management system current, carry out variance analyses and make corrections while the production documentation is updated during the manufacturing process so that a further employee can take up at the same point and continue the part. That is so immensely important because most of our parts are single parts, prototypes or smallest series which all possess individual specialities to be strictly and carefully observed. This way we are always capable to perform according to our customers’ orders and wishes during the manufacturing process and to adapt our production flow accordingly, modify and monitor it to achieve the best results.

Simultaneously the RM-PAS structures work out statistics on the quality of the parts during our daily work and while production continues, thus providing the fundamentals for the procedures according to DIN ISO 9001 / 9100 as well as the documentation, work instructions and the forms required to ensure the work flow in accordance with the demands of our quality management and to make necessary corrections. This enables us to permanently continue, maintain and monitor our work and production so that you, our customer, will always receive premium quality.

The task of invoicing, offering and management of human resources can be done by many standard application, but our self engineered software system RM-PAS provides all functionality to guide and manage the real task in production — the workflow itself.

You are curious about more details? So, please use the following link in order to get more information about our RM-PAS:

Destign and software engineering for RM-PAS is provided by: